Most warehouses and distribution centers rely on pallet racks to store loads of products until they are ready to be used or moved to another location. But a damaged or overloaded pallet rack can result in disaster, including damaged property, lost products and even injury or death.

Most warehouses and distribution centers rely on pallet racks to store loads of products until they are ready to be used or moved to another location. But a damaged or overloaded pallet rack can result in disaster, including damaged property, lost products and even injury or death.

One of the tenets to maintaining a safe warehouse is to always make sure your equipment is in optimal condition. Pallet racks are something many operators take for granted. After all, out of sight is out of mind. But should something go wrong and a pallet rack fails, it could cost your company time, money and even its reputation.

That’s why it’s critically important that any company using pallet racks create a regular inspection process to make sure the pallet racks you are depending upon are always living up to your expectations.

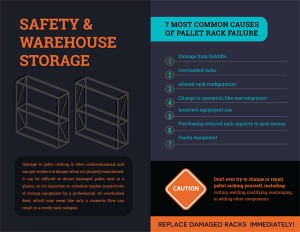

The most common causes of pallet rack failure are:

1. Damage from Forklifts — In warehouses and distribution centers, space equals money. So tight corners and small spaces are the norm rather than the exception. This can make operating a forklift challenging. The result is often collisions that cause dents and dings to pallet racks. These can add up to eventual failure.

2. Overloaded Racks — Pallet racks are graded according to the maximum weight they can bear. If you attempt to put too much strain on a pallet rack and exceeds its rating, the result could be total system failure.

3. Altered Rack Configuration — Pallet racks come in different designs and should always be used only according to the configuration recommended by the manufacturer. If you try to get your pallet racks to do something they weren’t designed to do, you may be disappointed with the results.

4. Change in Operation, Like Rearrangement — Moving your pallet racks around to frequently can cause them to lose their stability and strength. Your best bet is to find the best configuration that falls within the manufacturer’s intended use, and stick with it.

5. Incorrect Equipment Use — Any equipment, including pallet racks, should only be used according to their intended operational protocols. If you try to use pallet racks incorrectly, they may fail, resulting in potential damage, loss and injury.

6. Purchasing Reduced Rack Capacity to Save Money — Cutting corners by buying pallet racks with a lower weight capacity isn’t a good solution because it may cost you even more money down the line in lost or damaged product, or even fines and damages from injuries or deaths caused when they collapse.

7. Faulty Equipment — Inspecting your pallet racks regularly is critically important to their continued safe use. Faulty equipment such as damaged racks are simply an accident waiting to happen.

If your pallet rack inspections identify damaged or faulty equipment, you shouldn’t try to repair the pallet racking yourself by cutting, welding, modifying, rearranging or adding other components. Instead, consult the manufacturer. If it is still under warrant, you may be eligible for a replacement or refund.

You may have to replace the damaged pallet rack at your own expense. Yet this is a better solution than risking property and health. Replace damaged racks immediately!