Editor’s Note: This is the second in a series of blogs examining the most efficient and affordable ways to optimize existing warehouse space

Editor’s Note: This is the second in a series of blogs examining the most efficient and affordable ways to optimize existing warehouse space

Thanks to near universal access to the Internet and web’s elimination of geographic boundaries, many companies today are turning to e-commerce as a way to increase their customer base. While this usually results in more business, it also typically requires more warehouse space.

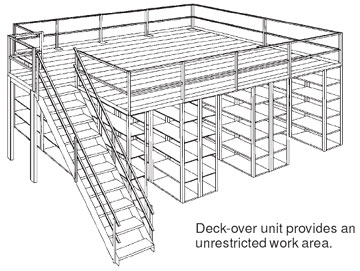

One of the most efficient and cost-effective ways to optimize your existing space — without having to invest heavily in new construction or renovations — is to install work platforms. These sturdy, steel structures allow warehouse operators to utilize vertical space, maximizing their cost-per-square-foot.