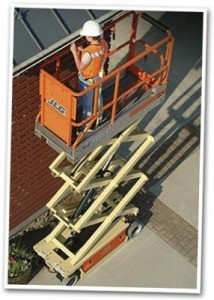

Operating an aerial lift , whether it is a scissors lift, articulating boom lift, telescopic boom lift or another type, presents actual a variety of dangers to both workers using the lifts and others in the area.

Most lifts are powered by hydraulics, so there is always the risk of a crushing injury whenever the lift it raised or lowered. Make sure that your work area, particularly under your lift, is clear before lowering your work plat form. Conversely make sure your overhead area is clear as well. Keep your hands inside the basket at all times; this means inside. Having your hand on the railing does not count as being in the basket.

When extended, there’s always the risk that a lift can tip over, especially when being used outdoors during windy weather conditions. Outdoor, all terrain lifts and some indoor “boom” lifts will come with extensions that can be put into place to level and further support aerial work platforms. Remember to avoid steep grades when driving the lift and never extend a platform that is not level.

Then there is the risk of the lift becoming caught on something or smashing something, especially when being used indoors. Knowing the lift’s turn radius will help avoid obstacles. Remember even lifts that are the same make and model can handle and drive very differently, so taking one for a spin to check the driveablity is not a bad idea; especially if you will be working in very close spaces.

Employee Aerial Lift Safety Training

Given the dangers, it is essential that any employee required to use an aerial lift be thoroughly trained on both its operation and safety procedures. Many aerial lifts come with a complete Aerial Lift Safety Program, often with downloadable video tutorials, testing and certification elements.

If the lift did not come with a training module, contact the manufacturer who can point you to a program specifically for your model. Or you can search online for a general training program such as the one created by the University of Kentucky.

Managers and supervisors should oversee employee training and keep records regarding which employees have completed the course. Only those employees who have gone through the entire course and passed any testing modules should be allowed to work with an aerial lift.

Safety through Teamwork

Ariel lifts should be operated by employee teams, including at least two operators and one supervisor. The first employee serves as the lift operator. The second is the “spotter”, watching for any potential collisions and warning people in the area that the lift is in use. The supervisor’s role is to make sure all safety procedures are being followed and that the work environment is hazard-free.

Are Personal Fall Protection Harnesses Required?

Fall restraint equipment consists of of a full body harness and a electrically non-conducive, shock absorbing lanyard. The lanyard should be attached to the harness on one end and an anchor point on the lift at the other. While the US Occupational Health and Safety Administration (OSHA) does not require the use of Personal Fall Restraint Systems (PFRS)they should be used by any employee on the work deck of an aerial lift.

Harnesses protect the employee in the case of a fall. Operators who wear a PFRS are less likely to be injured or killed should they accidentally fall from the platform. The proper use of a PFRS should be included in your company’s employee aerial lift training program.