The US Occupational Health and Safety Administration was created by the Workplace Safety Act passed by the US Congress and signed into law by then-President Richard Nixon in 1970. Since then, the agency has investigated thousands of workplace accidents and helped reduce workplace deaths by 62% and employee injuries by 42%.

The US Occupational Health and Safety Administration was created by the Workplace Safety Act passed by the US Congress and signed into law by then-President Richard Nixon in 1970. Since then, the agency has investigated thousands of workplace accidents and helped reduce workplace deaths by 62% and employee injuries by 42%.

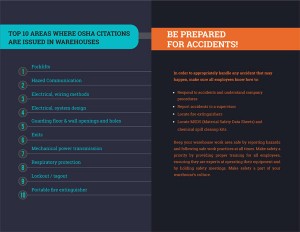

As a result of its nearly five decades of investigating workplace accidents, agency investigators have been able to identify the ten biggest problem areas in any workplace:

1. Forklifts — Yes, these heavy vehicles make the process of moving heavy loads from place to place easier, but they also can be potentially dangerous because operators can’t always see where they are going and pedestrians don’t always know they are in the area. The key to forklift safety is thorough operator training and constantly watching out for trouble.

2. Hazed Communication — Let’s face it: Warehouses and manufacturing facilities are loud. They also tend to be big, so sounds don’t carry very well. Using loud horns, flashing lights and other over-amplified warnings are the safest way to let everybody know about potential dangers.

3. Electrical Wiring, Wiring Methods — One of the best ways to avoid fires, explosions and other accidents is to make sure your electrical wiring is in optimal condition. Unfortunately, in busy warehouses, electrical equipment such as outlets, junction boxes and other electrical methods can easily become damaged.

4. Electrical, System Design — The best way to prevent electrical equipment from being damaged is to keep it out of the line of traffic from forklifts and other vehicles.

5. Guarding Floor and Wall Openings and Holes — It’s easy to punch holes in walls, damage floors and cause other potentially dangerous damage when forklifts, power jacks and other heavy machinery are being used. The best way to maintain safety is to keep your facility in optimal condition and repair damage immediately.

6. Exits — If there is a fire, explosion or accident and an evacuation of your facility is required, it needs to take place both immediately and orderly. That means exits need to be clearly marked and always kept clear of obstacles. Exit signs need to be always lit and in working condition, and workers should be trained and frequently drilled on the proper evacuation protocols.

7. Mechanical Power Transmission — Train workers to keep a safe distance from any type of equipment that has moving parts.

8. Respiratory Protection — Personal protection equipment such as masks or respirators must be used whenever materials are being used that could potentially cause breathing problems.

9. Lockout/Tagout –Locks and lockout tags let everybody know about equipment that is damaged or inoperable.

10. Portable Fire Extinguishers — Fire extinguishers that are charged and ready for use should be located throughout your facility. In many jurisdictions, this is required by law.

Your safety procedures and equipment are only as good as how well you train your workers to follow and use them. To be assured your facility is ready for any type of accident, make sure your employees know how to respond to accident and follow proper procedures. They also should report any accidents immediately to supervisors, know how to locate the nearest fire extinguisher, and know where your Materials Safety Data Sheets are located.

Making safety a part of your company’s culture is the best course of prevention.