If you are looking for ideas to improve the efficiency of packaging, manufacturing or over materials handling, you need to look no further than your computer’s mouse. If you turn over a mechanical computer mouse, you will find is operated by a small rubber or plastic trackball that controls where the cursor on your computer screen is located.

If you are looking for ideas to improve the efficiency of packaging, manufacturing or over materials handling, you need to look no further than your computer’s mouse. If you turn over a mechanical computer mouse, you will find is operated by a small rubber or plastic trackball that controls where the cursor on your computer screen is located.

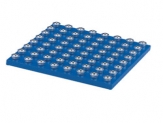

Apply that same technology hundreds of times and you get a ball transfer unit, a piece of materials handling equipment that is indispensable in many warehousing and manufacturing operations.

How Ball Transfer Units Work

Ball transfer units allow you to convey packages, assembly parts and other materials in every direction with minimal friction or interference. They use easy running balls and medium-heavy and heavy plates to smoothly move containers with smooth surfaces through production lines, shipping assembly areas and other areas where speed and efficiency is required.

Typically, ball transfer units are composed of a single large ball — usually made of steel but sometimes made of plastic or even wood — that is supported by smaller ball bearings. These allow the ball the move Omni-directionally smoothly. When a series of these units are mounted inside a restraining fixture, the result is a ball transfer unit.

Variety of Sizes and Uses

Ball transfer units come in many different sizes and they can be used individually or combined with other ball transfer units to create a pathway for products or parts to move up, down and sideways through a production or shipping area. When objects are moved quickly across an array of ball transfer units, it’s known as a ball transfer table, which is a type of conveyer system.

Unlike conveyor belts or other types of mechanical or electronic production lines, ball transfer units don’t require any type of outside power, depending exclusively on the momentum of the object or external force to convey the object to its desired location. Consequently, in some applications ball transfer units can result in energy cost savings, as well as reduced maintenance and repair costs.

Example of Common Applications

One of the most common examples of ball transfer tables are luggage delivery carousels in airport baggage claim areas. But ball transfer tables have multiple industrial, manufacturing and warehousing applications as well.

Prior to the development of the ball transfer unit — which was first patented in 1958 by Autoset Production Ltd. — inverted casters were commonly used to transport objects through work areas. But the problem with casters is that they recognize a trail. In other words, caster wheels need to be aligned before directional change can be achieved. Ball transfer units solved this problem.

In the same way that it is possible to put too much pressure on your mechanical computer mouse so that it doesn’t work properly, ball transfer units can be affected by load bearing limitation as well as by the surface of the objects moving across them. But some ball transfer table manufacturers have addressed this problem by developing units with re-circulating ball principles.

If you are seeking to improve the flow of your warehouse, manufacturing or shipping facility, check out the ball transfer tables as well as the roller and belt conveyors available at Bahrns.com.